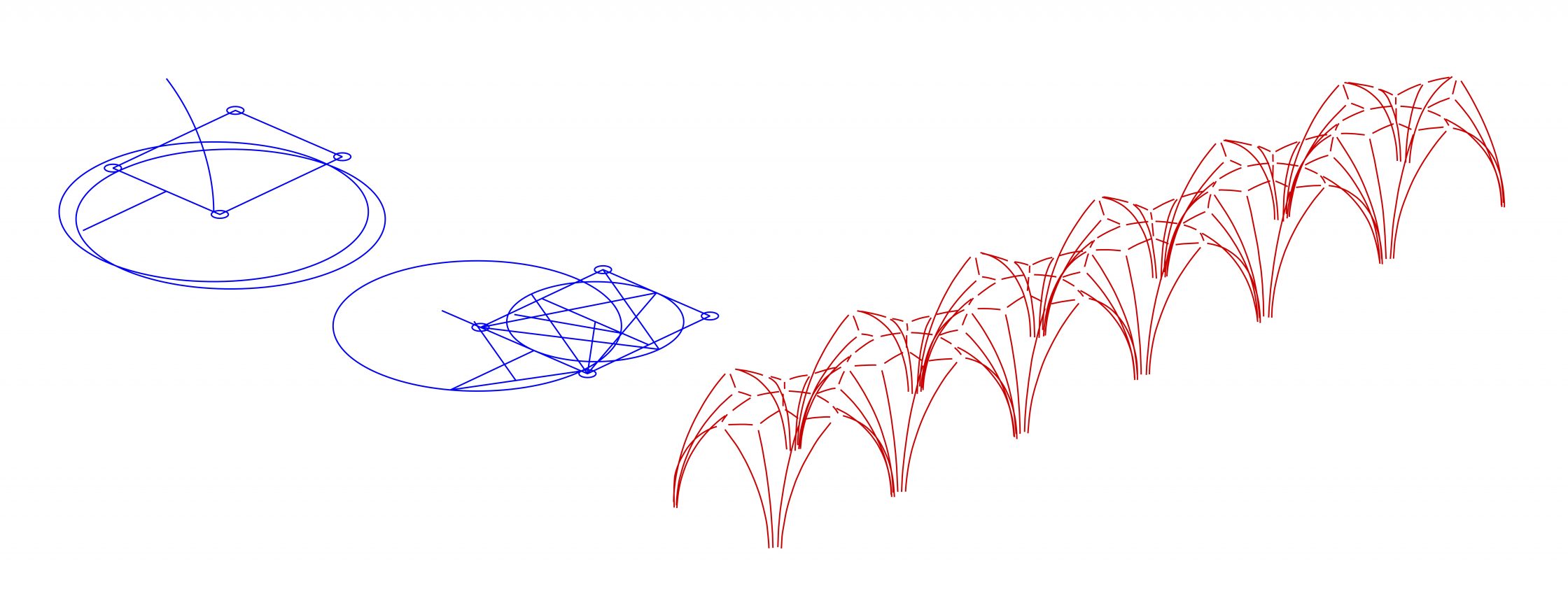

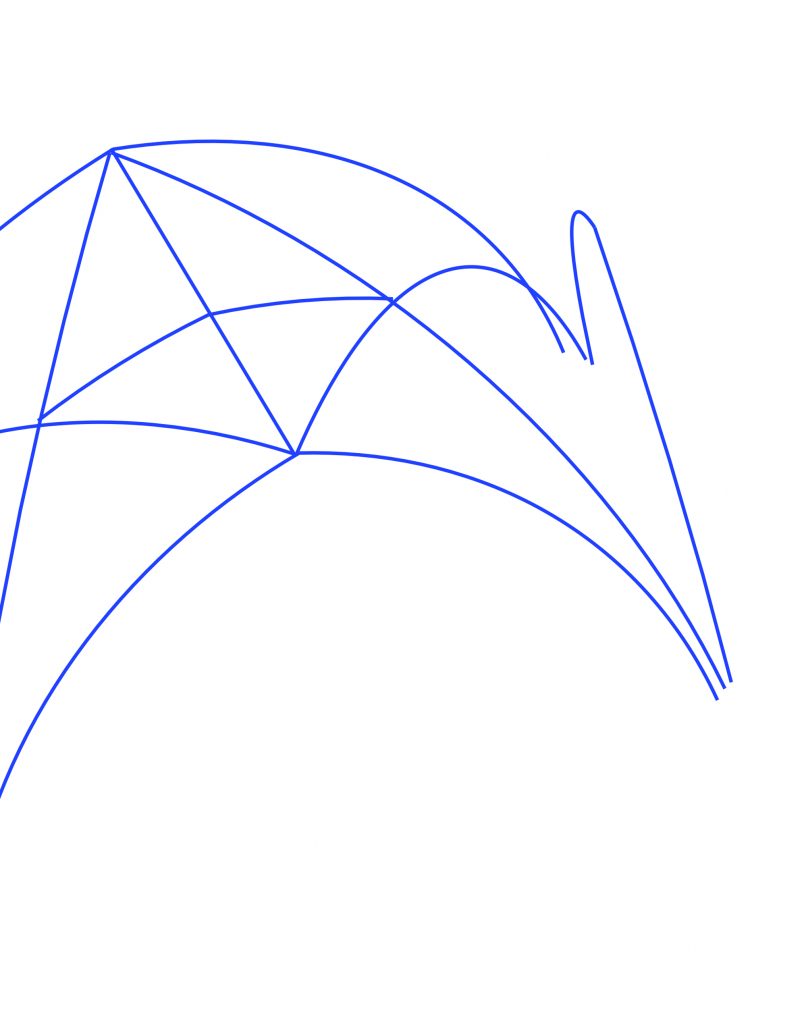

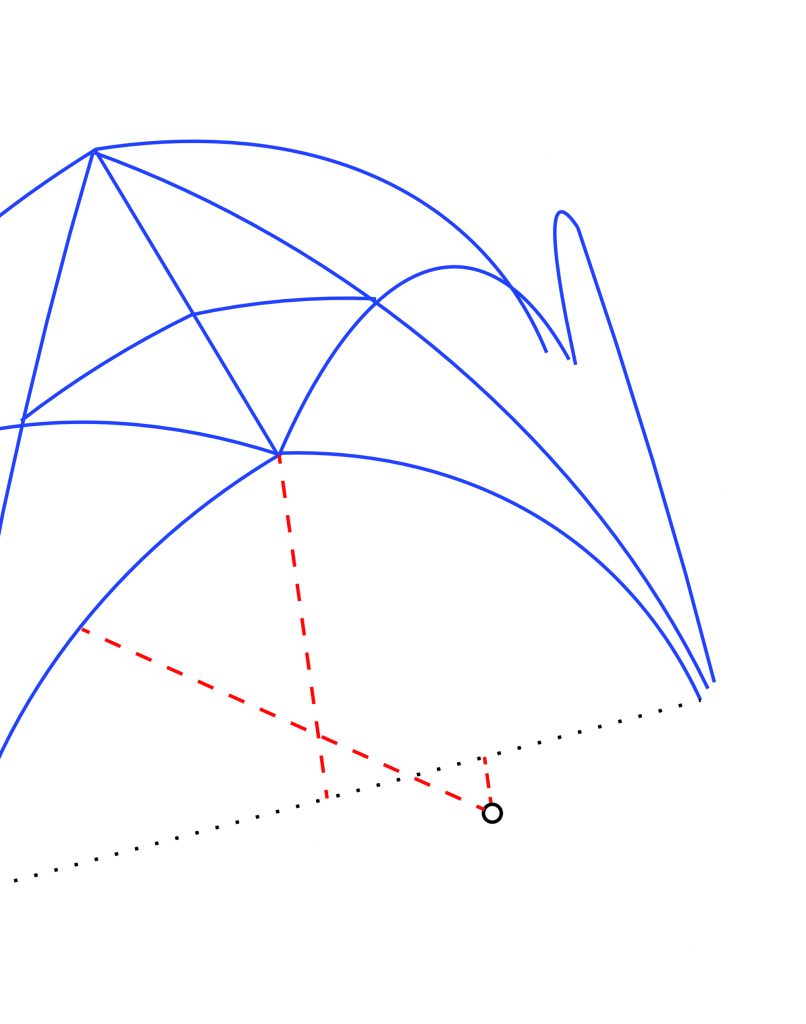

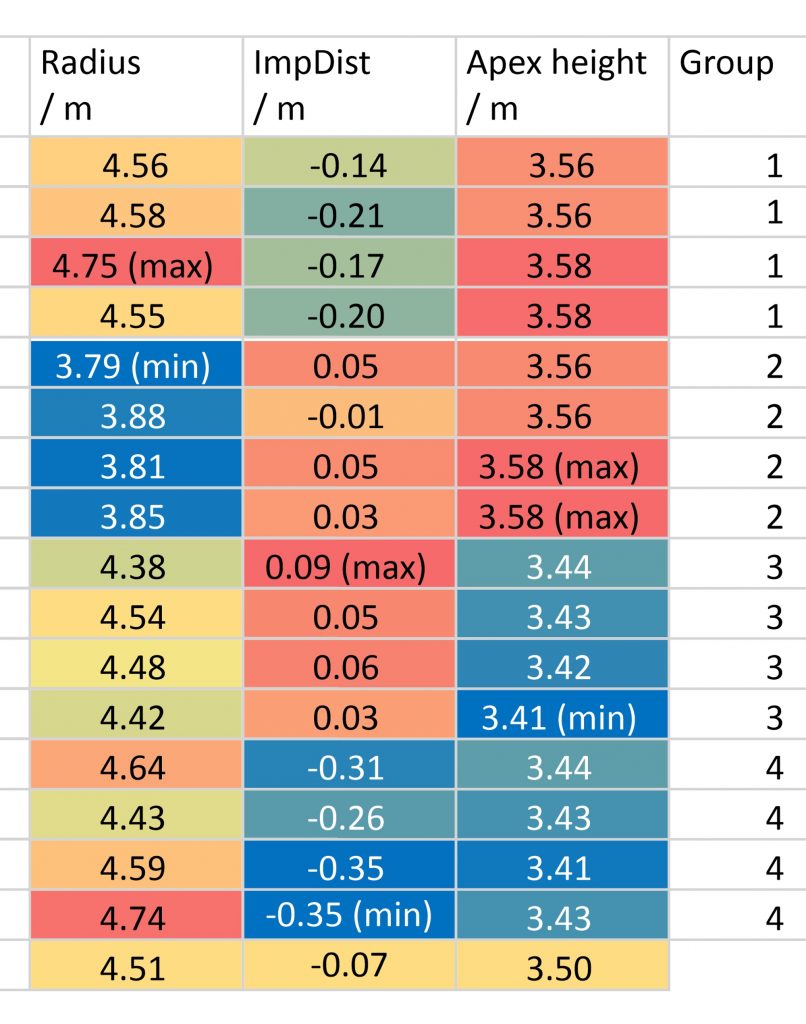

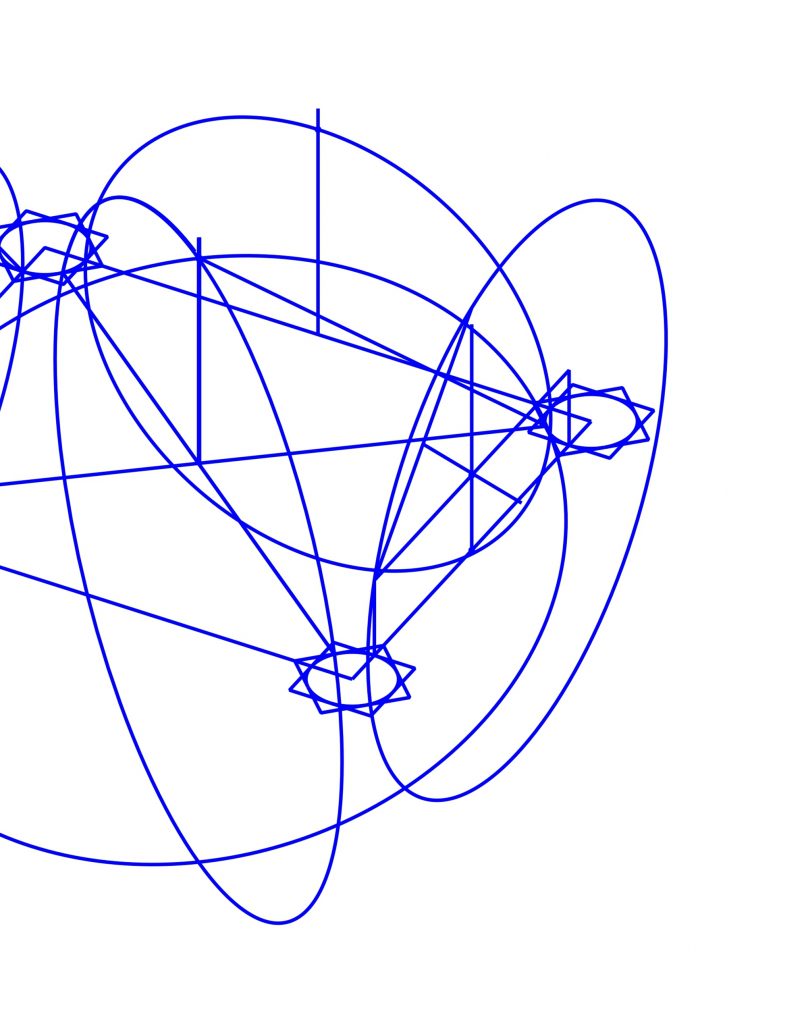

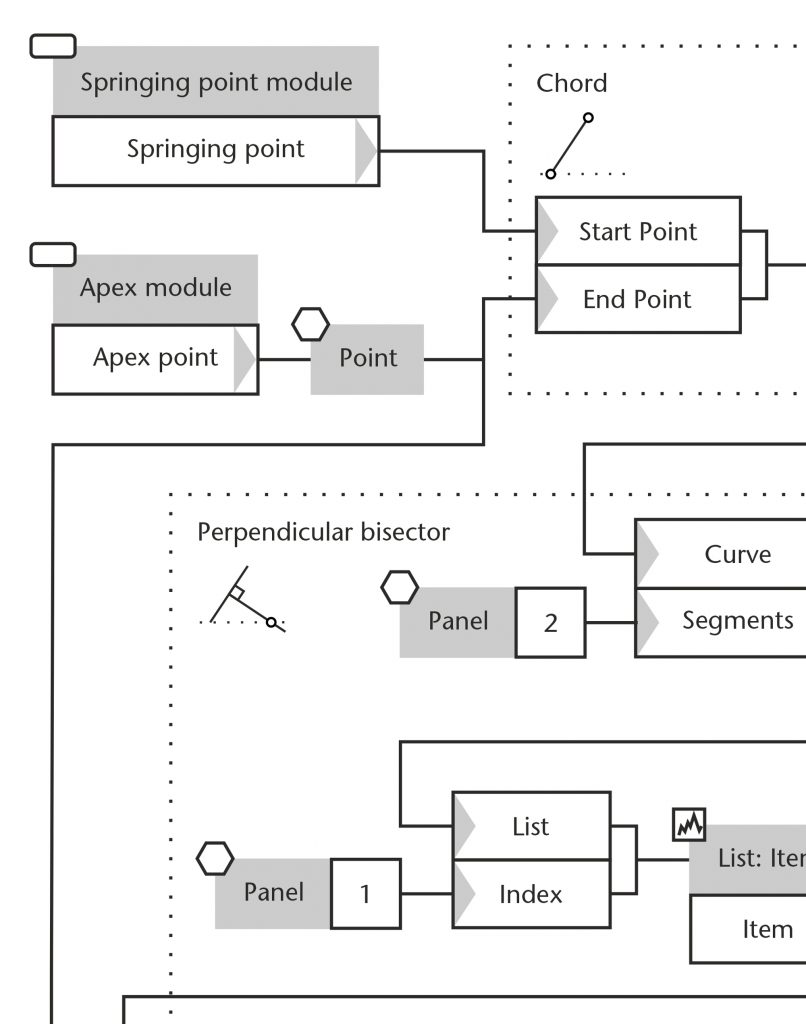

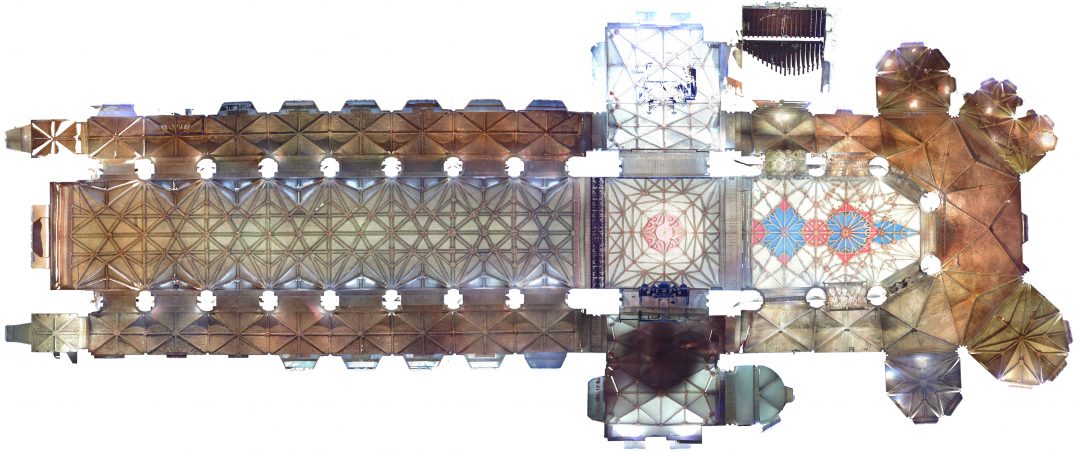

Analysing our laser scanning data is a complex, multistage process involving a wide range of digital techniques. First, our mesh models need to be converted into a form which can be measured directly. The intrados lines of the ribs are traced using 3D modelling software and a set of best fit arcs created, allowing the geometry of their curvatures to be quantified. Measurements are taken and tabulated for the purposes of statistical analysis, enabling us to assess their accuracy and study the geometrical relationships between them. By interpreting this data, we are able to produce a set of hypotheses for how the individual ribs of each vault were designed, as well as how these could be combined into coherent design sequence. Once a hypothesis has been developed, we test its validity using parametric modelling, producing an idealised version of the design which can be compared directly to the laser scanning data. Any differences between the two models are then investigated and the hypothesised revised to accommodate them. The analytical process is therefore a prolonged form of trial and error, with our hypothesis being gradually refined until we achieve the closest possible match between theoretical process and practical reality.

Analysing